Modernizing Equipment

Engineering Mineral Fertilizer Production

About ReFur

The company specializes in the modernization of equipment for chemical production plants, particularly for mineral fertilizer manufacturing.

Our specialists have experience in upgrading existing units and developing new reactors, converters, and furnaces for ammonia, nitric acid, and other chemical processes.

Development and modernization scope includes:

Our Main Focus Areas

Ammonia converters

Catalytic oxidation of ammonia with oxygen from atmospheric air at various operating pressures.

HCN converters

Catalytic oxidation of a mixture of ammonia and natural gas with oxygen from atmospheric air.

Fired heaters

Heating furnaces using an open flame to heat process media.

Selective tail gas treatment reactors (SCR)

Selective catalytic reduction of nitrogen oxides with ammonia over a catalyst in weak nitric acid production.

High-complexity heat-exchange equipment

Custom-designed heat exchangers with combined radiant and convective heat-transfer zones.

Non-selective tail gas treatment reactors (NSCR)

Non-selective catalytic reduction of nitrogen oxides with natural gas over a catalyst in weak nitric acid production.

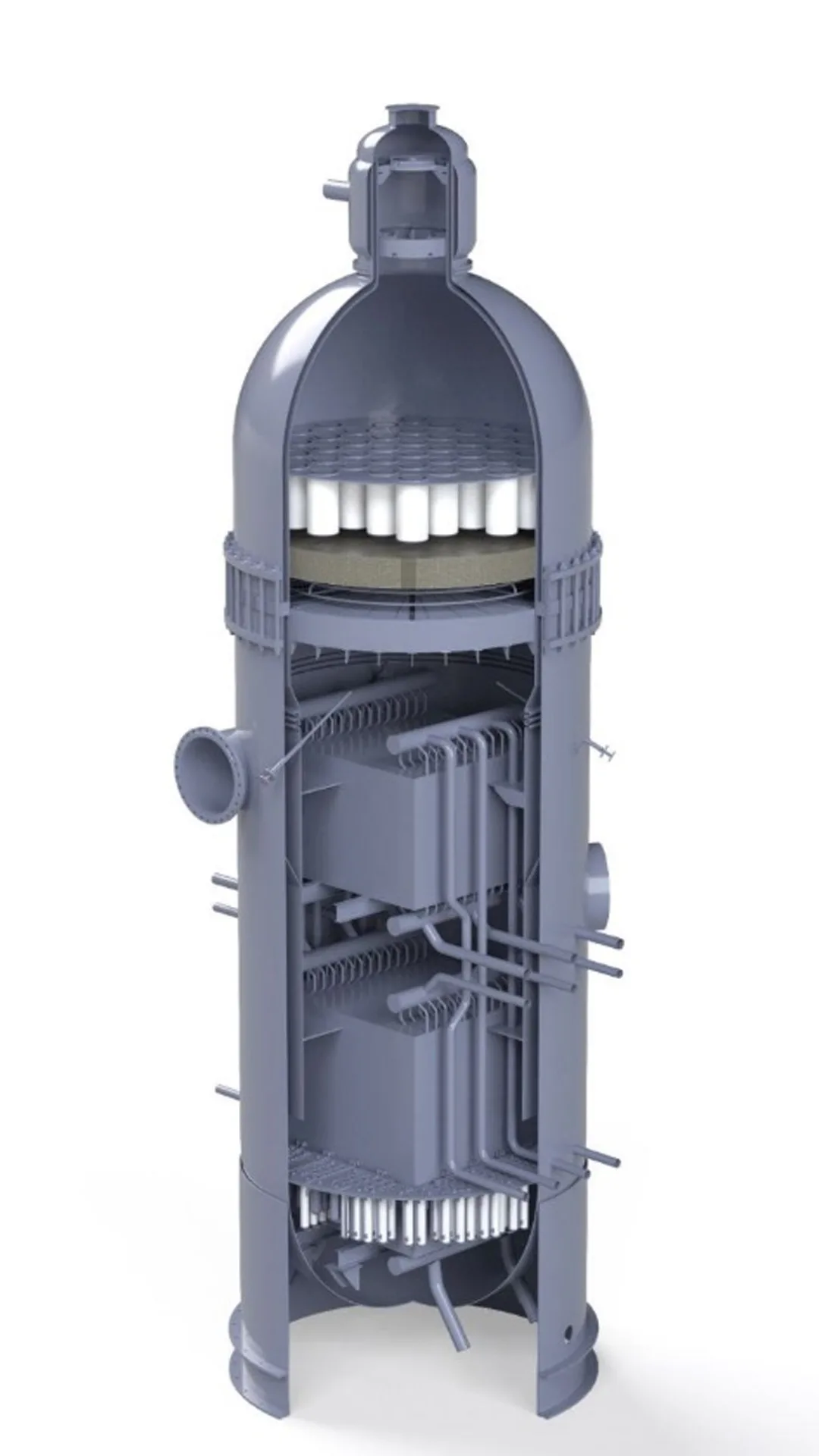

Ammonia Catalytic Oxidation Reactor AK-72 (Burner)

Technology

Production of weak nitric acid under dual-pressure conditions

Object name

Converter (Contact Apparatus)

Purpose

Catalytic oxidation of ammonia with oxygen from air

Operating pressure

0.2–0.37 MPa

Operating temperature

850–880 °C

Production rate of nitrous gas

215–290 t/h

Scope of work

Comprehensive modernization

Scope of modernization includes

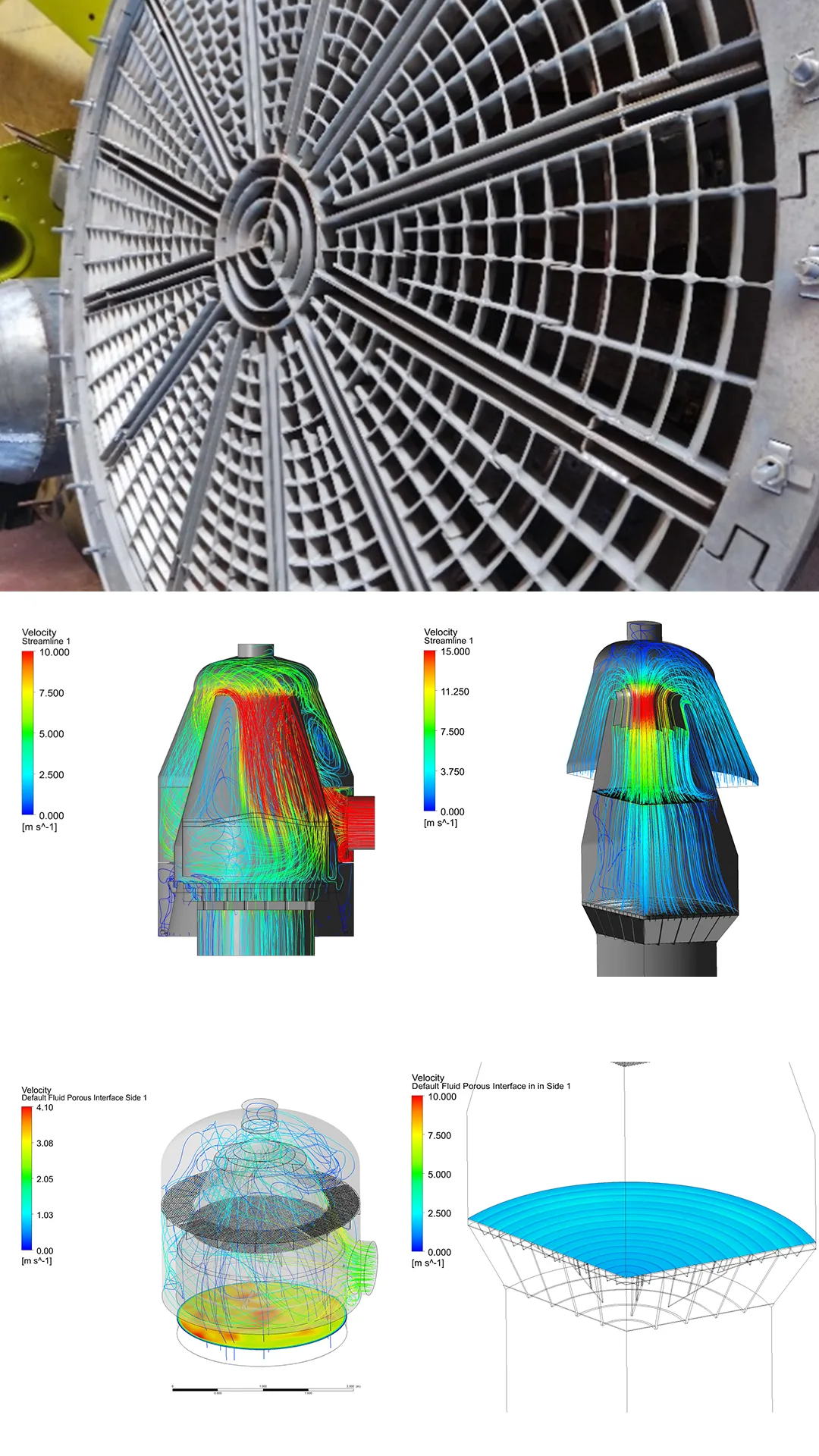

- Modification of the ammonia–air mixing unit

- Replacement of the catalyst package support system

- Installation of a precious metal recovery system

Achieved results after modernization

- Increased conversion rate

- Reduced irreversible precious metal losses

- Improved conditions for increasing plant capacity

Non-Selective Tail Gas Cleaning Reactor AK-72

Technology

Production of weak nitric acid under dual-pressure conditions with high-temperature non-selective tail gas cleaning

Object name

Catalytic cleaning reactor

Purpose

Removal of nitrogen oxides, including nitrous oxide (N2O), from the tail gas

Operating pressure

1.16 MPa

Operating temperature

520–780 °C

Flow rate of the treated exhaust gas

Up to 220,000 Nm3/h

Scope of work

Reconstruction

Scope of reconstruction includes

- Modification of the catalyst basket design and the mixing device

- Replacement of the granular catalyst APK-2 with a modern block-type catalyst

Achieved results after reconstruction

- Tail gas NOx removal efficiency: > 95%

- Tail gas N2O removal efficiency: > 95%

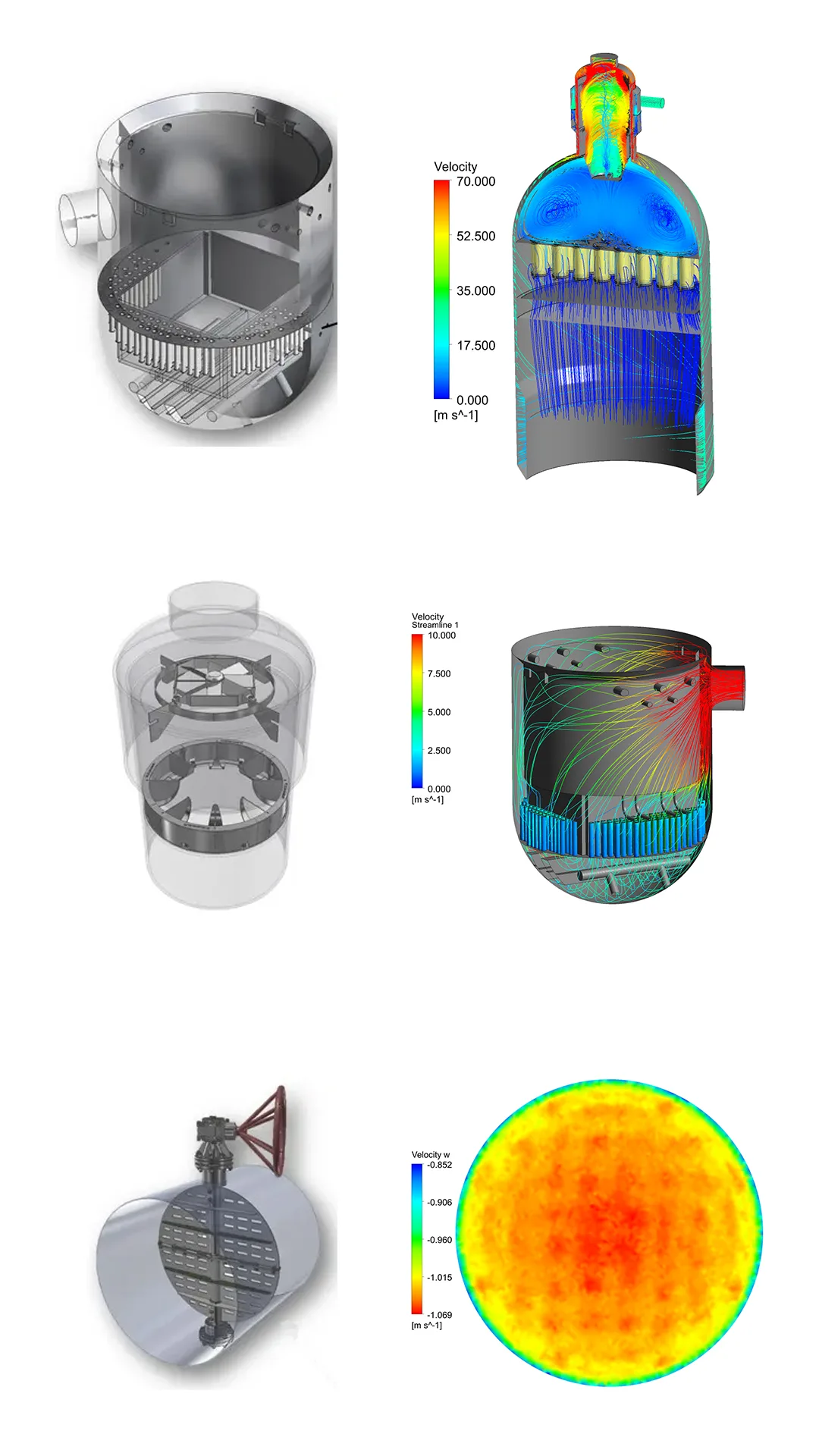

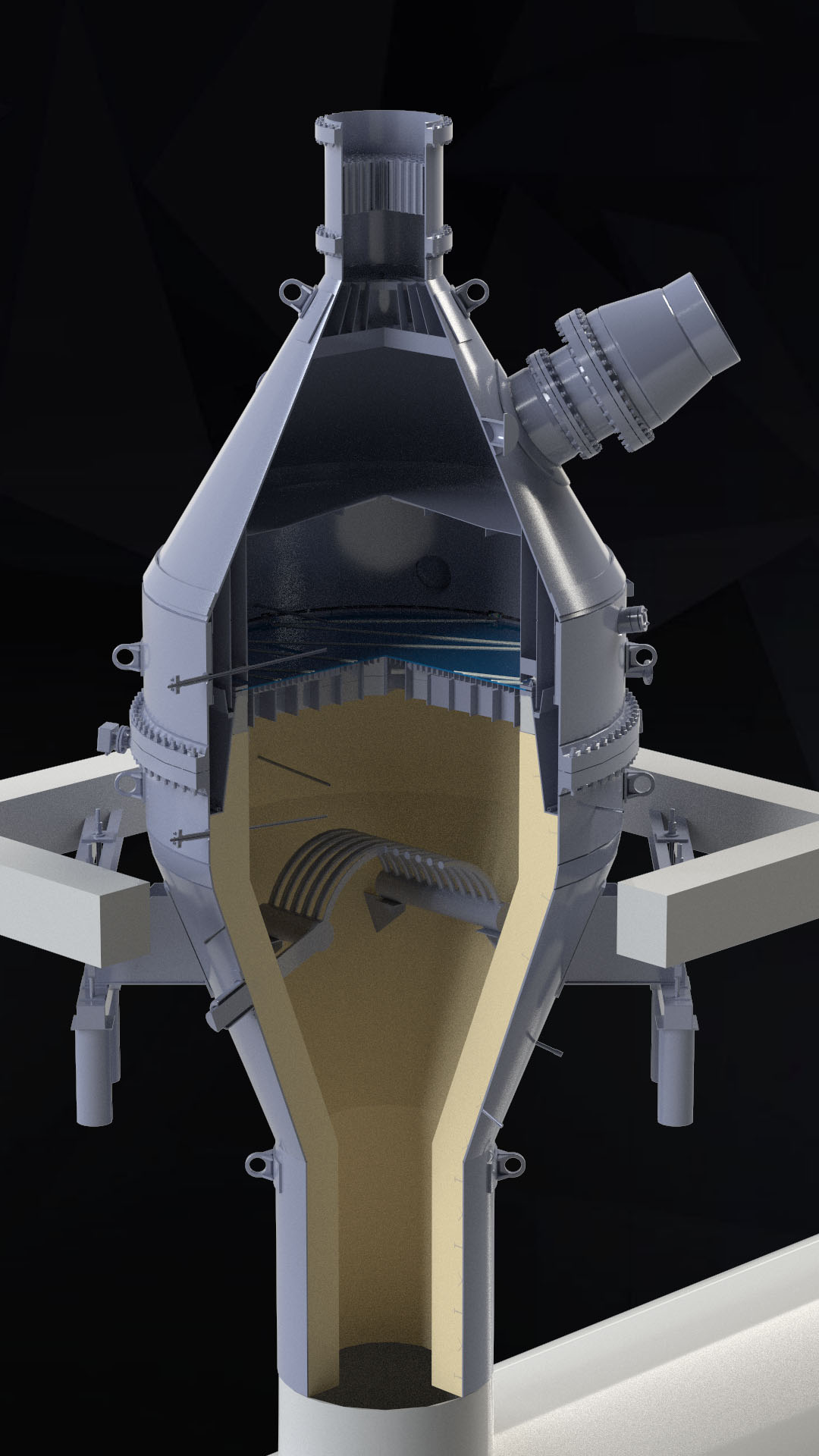

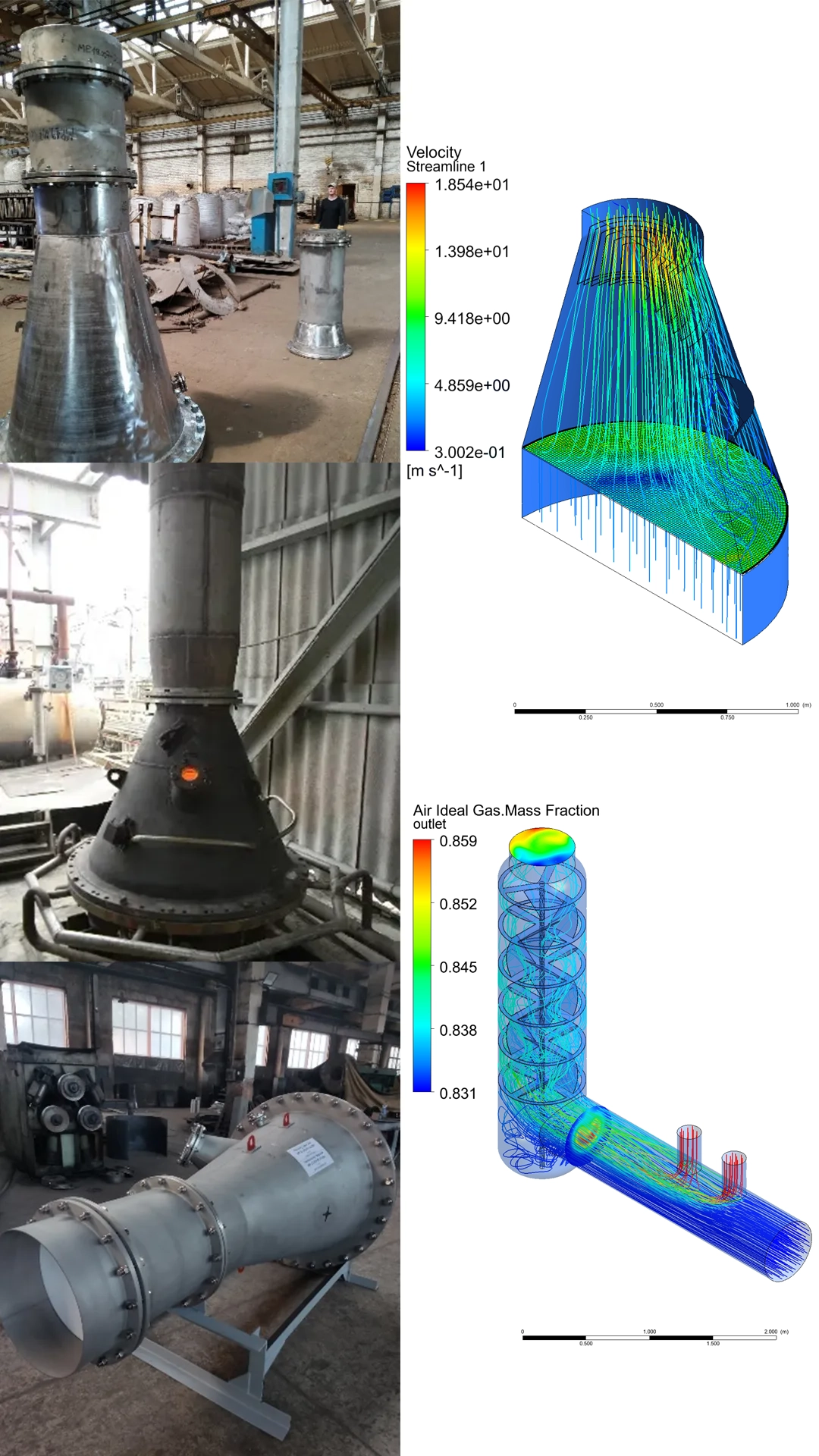

Ammonia Catalytic Oxidation Reactor UKL-7

Technology

Production of weak (non-concentrated) nitric acid under single-pressure operation at 0.73 MPa, with a capacity of up to 16.5 t/h

Equipment designation

Contact apparatus

Purpose

Catalytic oxidation of ammonia with oxygen from atmospheric air

Operating pressure

0.8 MPa

Operating temperature

850–950 °C

Nitrous gas production rate

Up to 62 t/h

Scope of work

Revamp (modernization)

Scope of revamp includes

- Installation of a newly designed catalyst support structure

- Revamp of the ignition system

- Revamp of the contact assembly with increased diameter

- Revamp of the gas distribution system at the inlet to the contact assembly

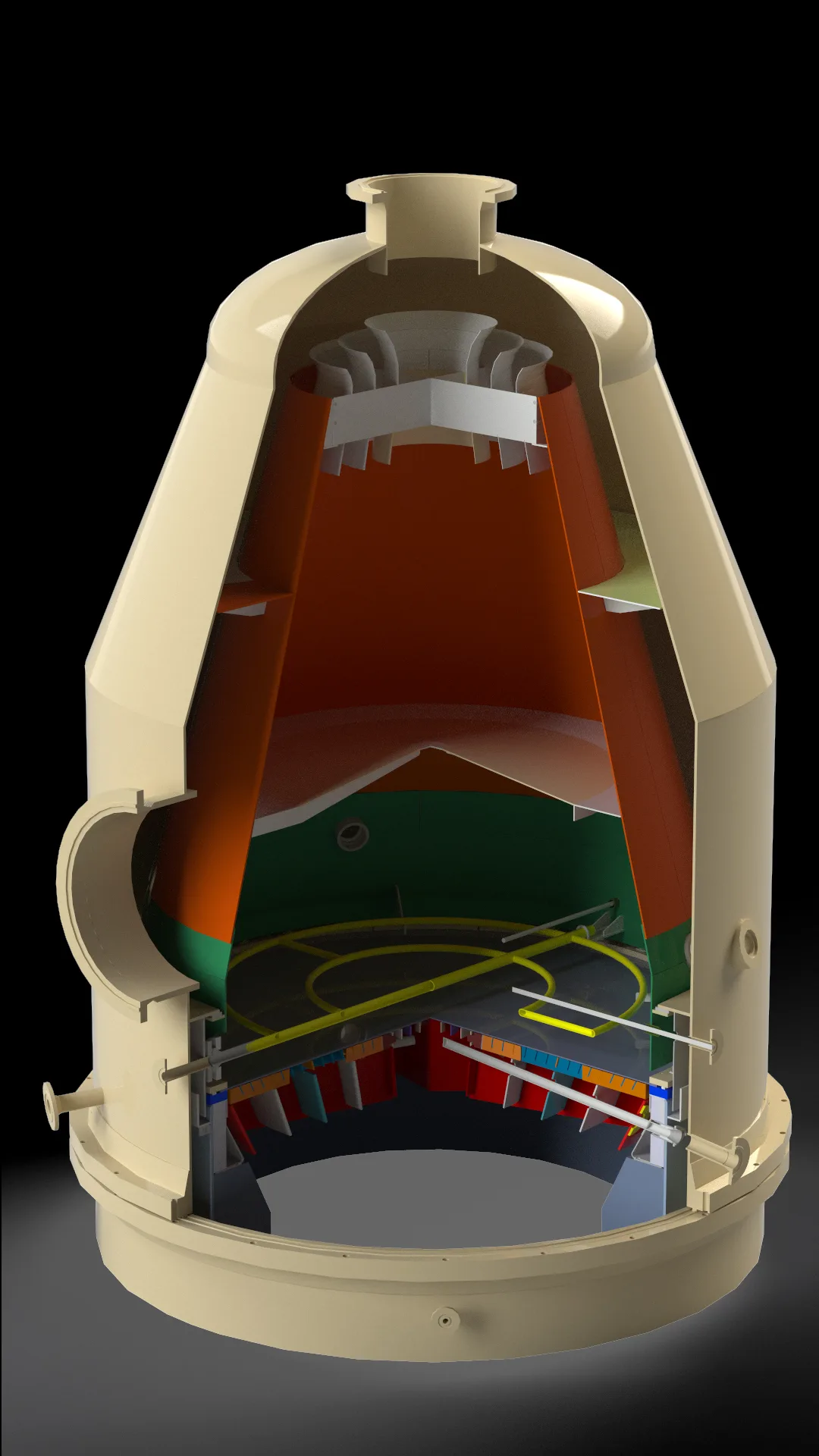

Advantages of the revamped unit

compared to existing designs

compared to existing designs

- Improved aerodynamic performance

- Higher throughput

- Higher conversion degree

- Extended service interval

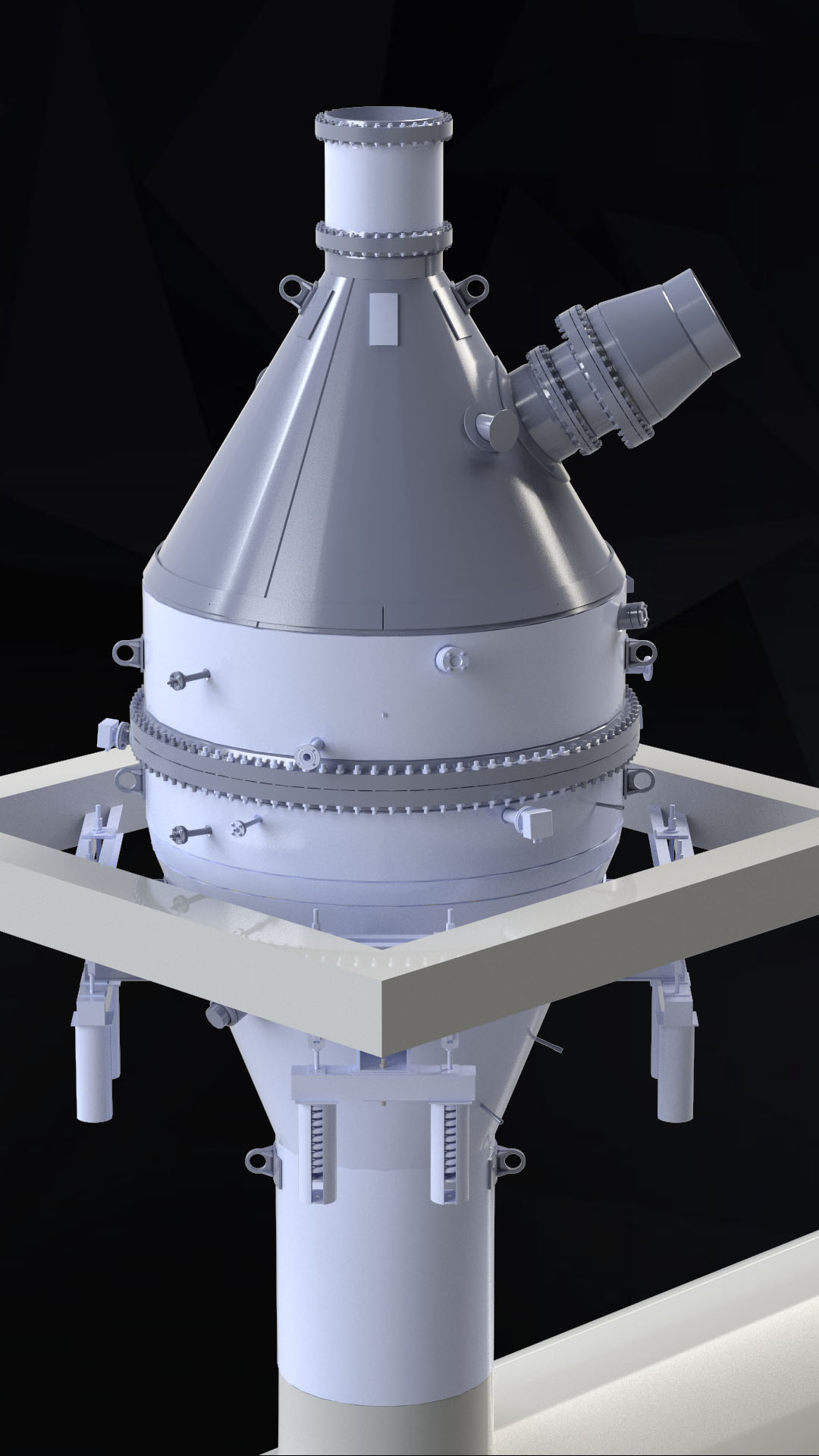

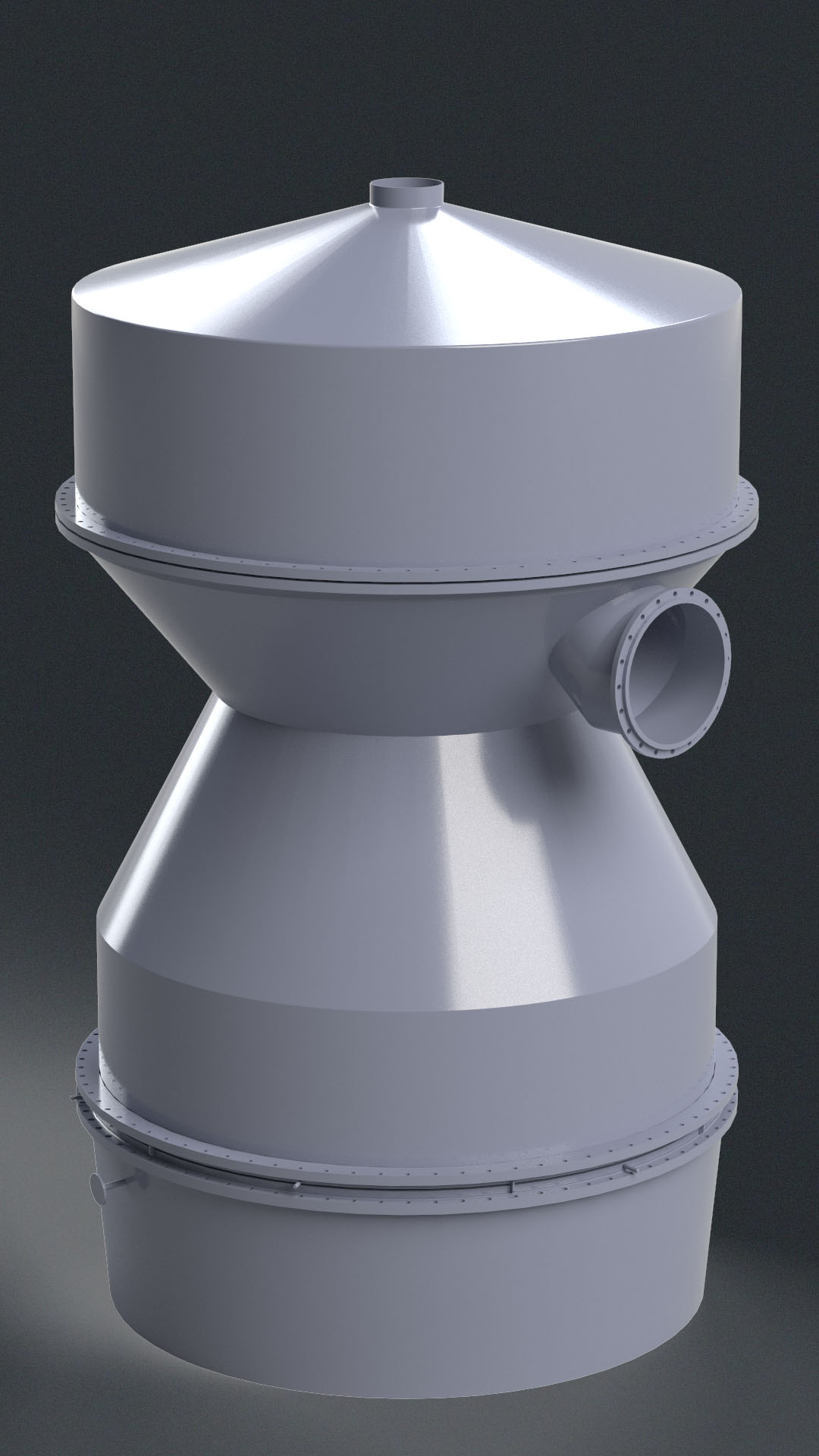

Ammonia Catalytic Oxidation Reactor UKL-7M (Burner)

Technology

Production of weak nitric acid under single pressure of 0.73 MPa

with a capacity of up to 20 t/h

with a capacity of up to 20 t/h

Object name

Converter (Contact Apparatus)

Purpose

Catalytic oxidation of ammonia with oxygen from air

Operating pressure

0.8 MPa

Operating temperature

250–950 °C

Production rate of nitrous gas

Up to 75 t/h

Scope of work

Design and manufacturing of a new reactor

Advantages of the new reactor

compared to existing units

compared to existing units

- Improved aerodynamic characteristics

- High throughput capacity

- Higher conversion rate

- Extended service life between maintenance intervals

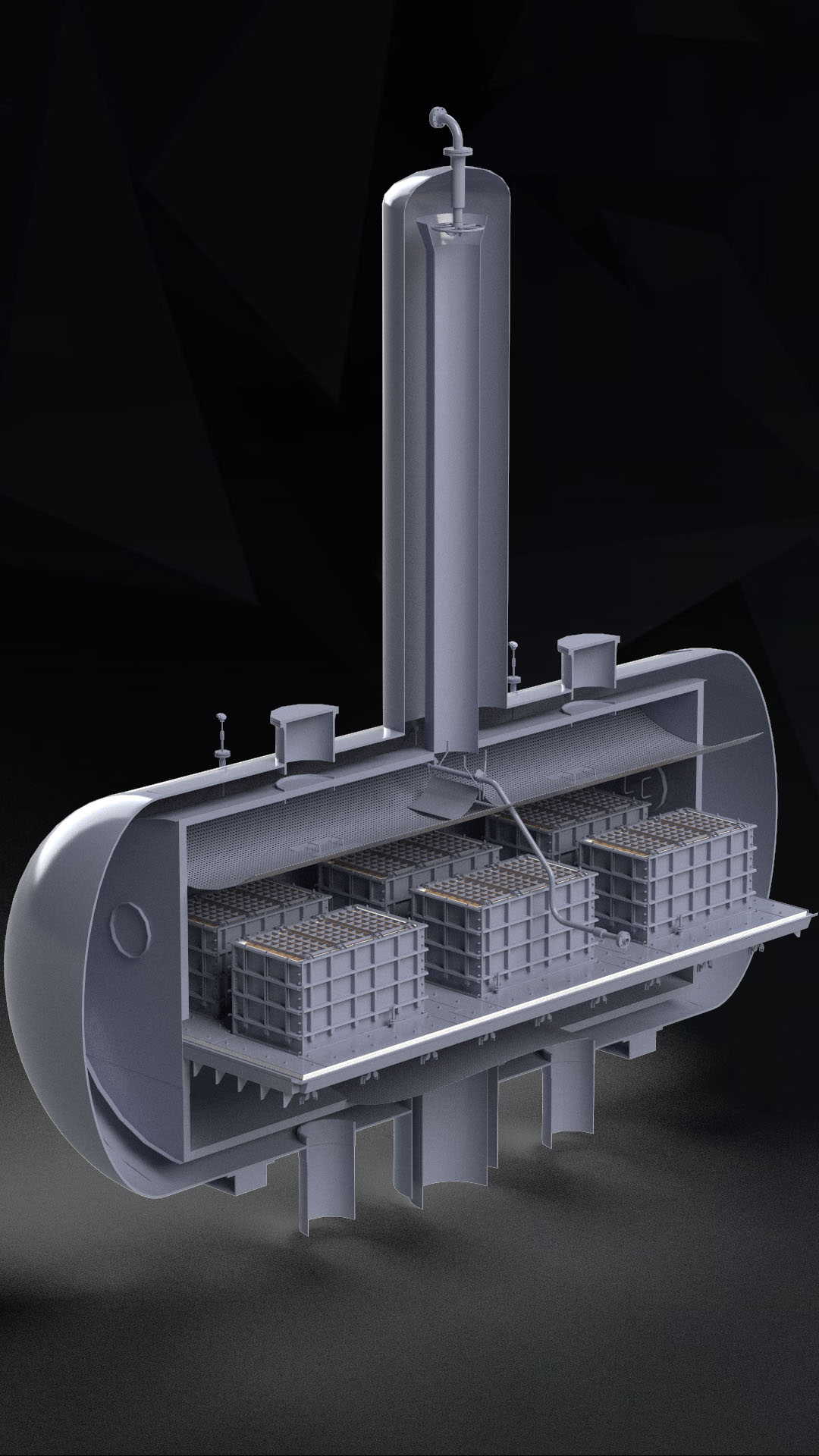

Ammonia Catalytic Oxidation Reactor (Burner) for ASAK-Type Units

Technology

Production of weak nitric acid under dual-pressure conditions / nitrite–nitrate salts

Equipment name

Contact reactor (Burner)

Purpose

Catalytic oxidation of ammonia with atmospheric oxygen

Operating pressure

Vacuum 50–200 Pa

Operating temperature

760–820 °C

Scope of work

Modernization

Modernization scope includes

- Installation of an ammonia–air mixture filter

- Installation of a catalyst-package supporting device

Achieved results after modernization

- Increased conversion rate

- Extended service interval

- Reduced irreversible PGM losses

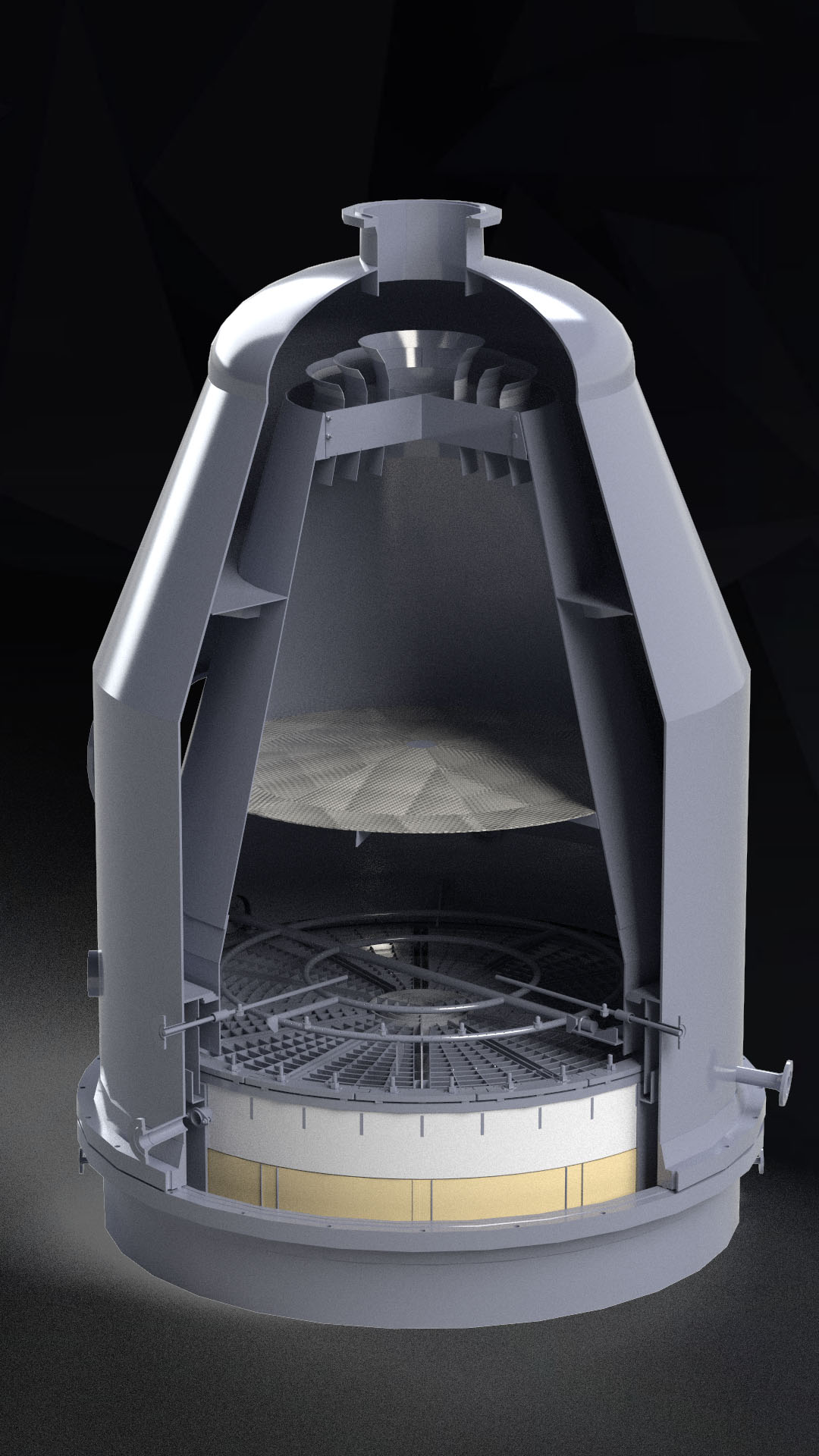

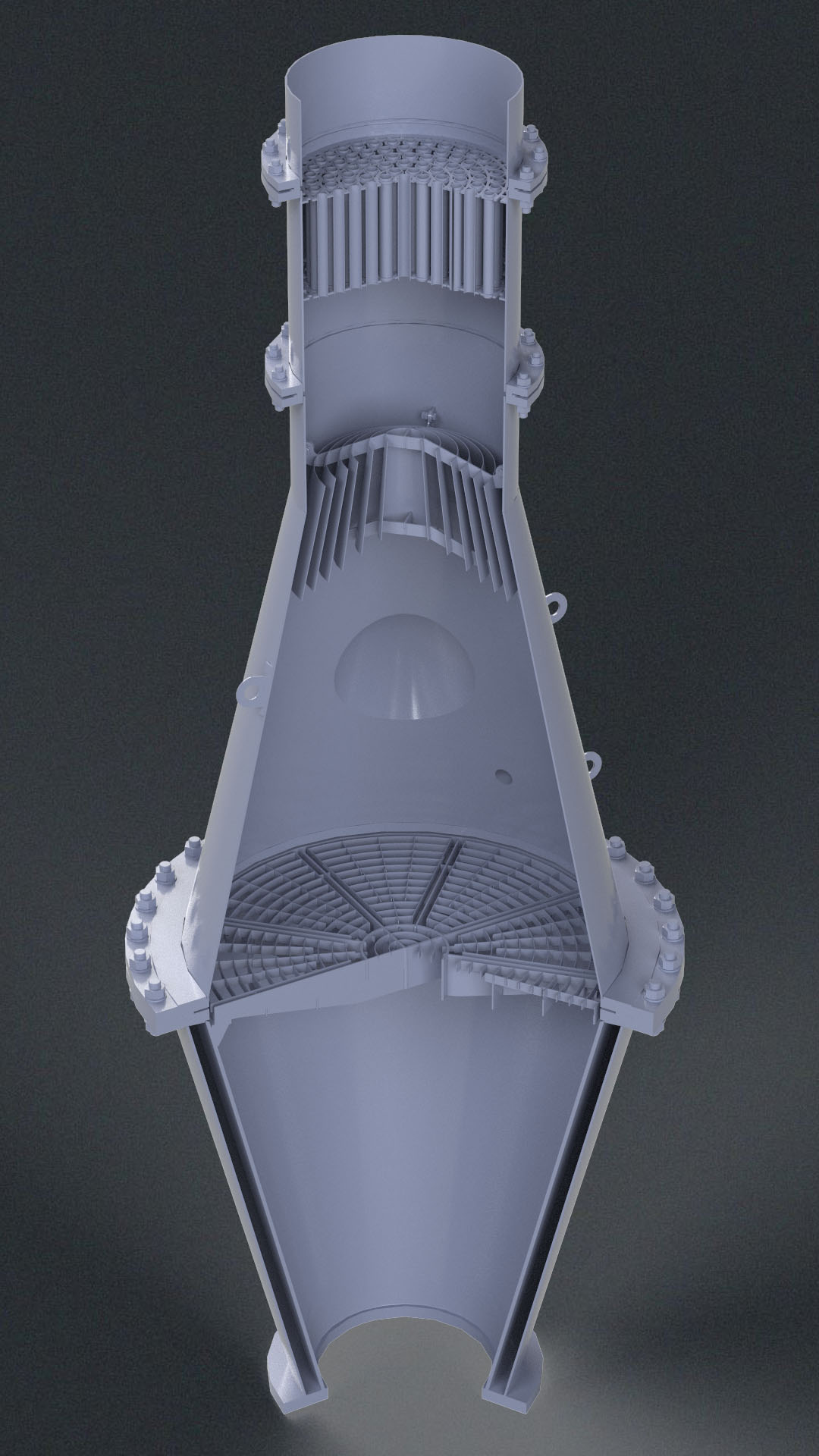

HCN Reactor

Technology

Hydrogen cyanide production

Object name

Converter (Contact Apparatus)

Purpose

Catalytic oxidation of an ammonia–methane mixture with oxygen from air

Operating pressure

0.1–0.2 MPa

Operating temperature

1000–1200 °C

Scope of work

Design and manufacturing of a new reactor

Differences of the new reactor

compared to existing units

compared to existing units

The new design of the reactor shell, together with redesigned gas-distribution

elements and a reinforced catalyst support system, ensures uniform flow distribution

and provides optimal operating conditions for efficient performance of the contact

apparatus.

elements and a reinforced catalyst support system, ensures uniform flow distribution

and provides optimal operating conditions for efficient performance of the contact

apparatus.

Achieved results

- Increased conversion rate

- Reduced precious metal losses

- Extended service interval

- Prevention of catalyst bed integrity violations

- Elimination of vibrations in the contact zone

- Uniform temperature distribution within the contact area

- Prevention of overheating and deformation of the reactor shell